Terminator E-mobile

The Terminator, as a slow single shaft shredder, can be used for all types of waste. The rotor / counter comb combination allows you to range from a coarse crushing to a fine crushing. The continuous adjustment of the cutting space allows to adapt the size of the piece to the next process. A hydraulic transmission, with adjustment of the number of revolutions according to the load, ensures the optimization of engine power on mobile models. (Available only in trailer or roll-off version)

Technical information

Other tech info

| Tipologia | Dimensione |

|---|---|

| Altezza di carico (mm) | 2596-3005 |

| Altezza di scarico (mm) | 3710-4250 |

Features

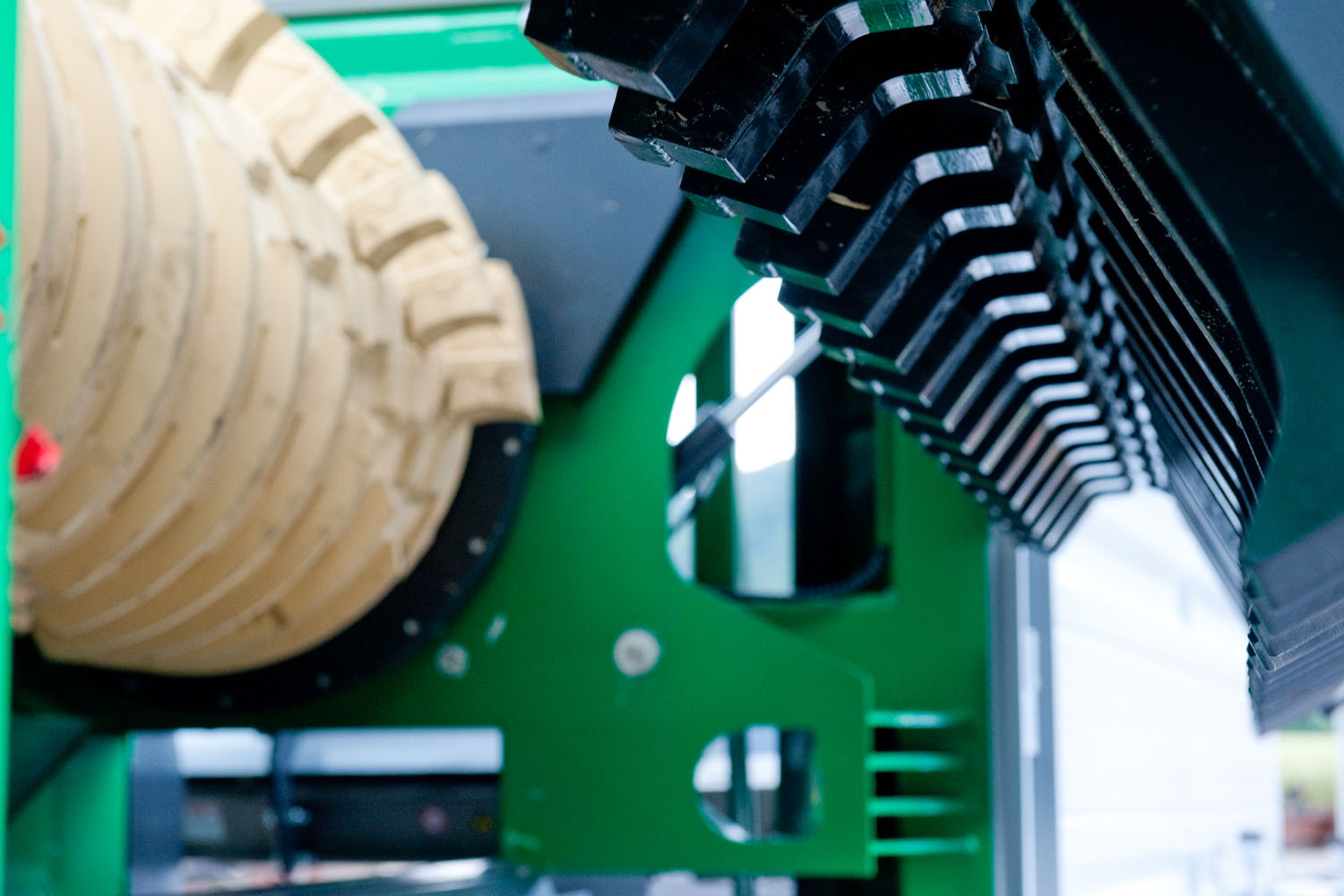

Terminator shredding rotor

The Terminator has three types of rotors available, to adapt to each job: ˝U˝ (Universal) ˝F˝ (Fine) ˝XXF˝ (Extra Fine). The different rotors guarantee different sizes according to the material to be obtained. The teeth can be reused several times, with a reduction in wear costs.

Chassis

Three types of frame available: on wheels, demountable and on tracks, in all possible variants, the machine immediately switches from transport to work position. The right frame for every surface and application.

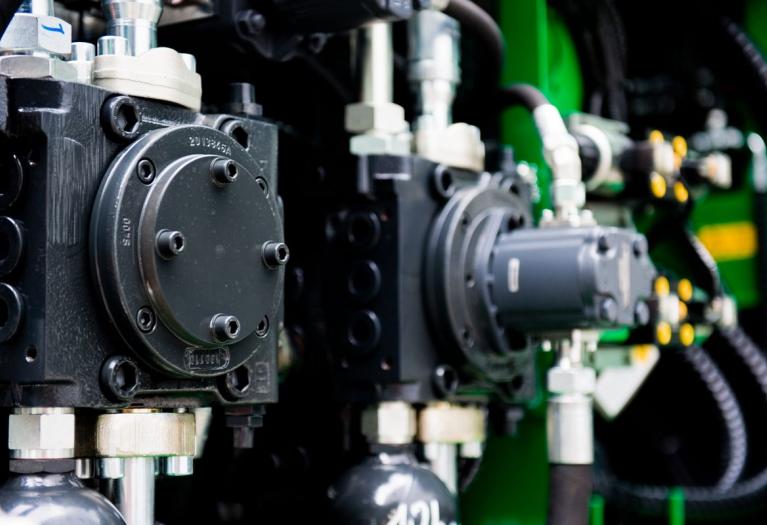

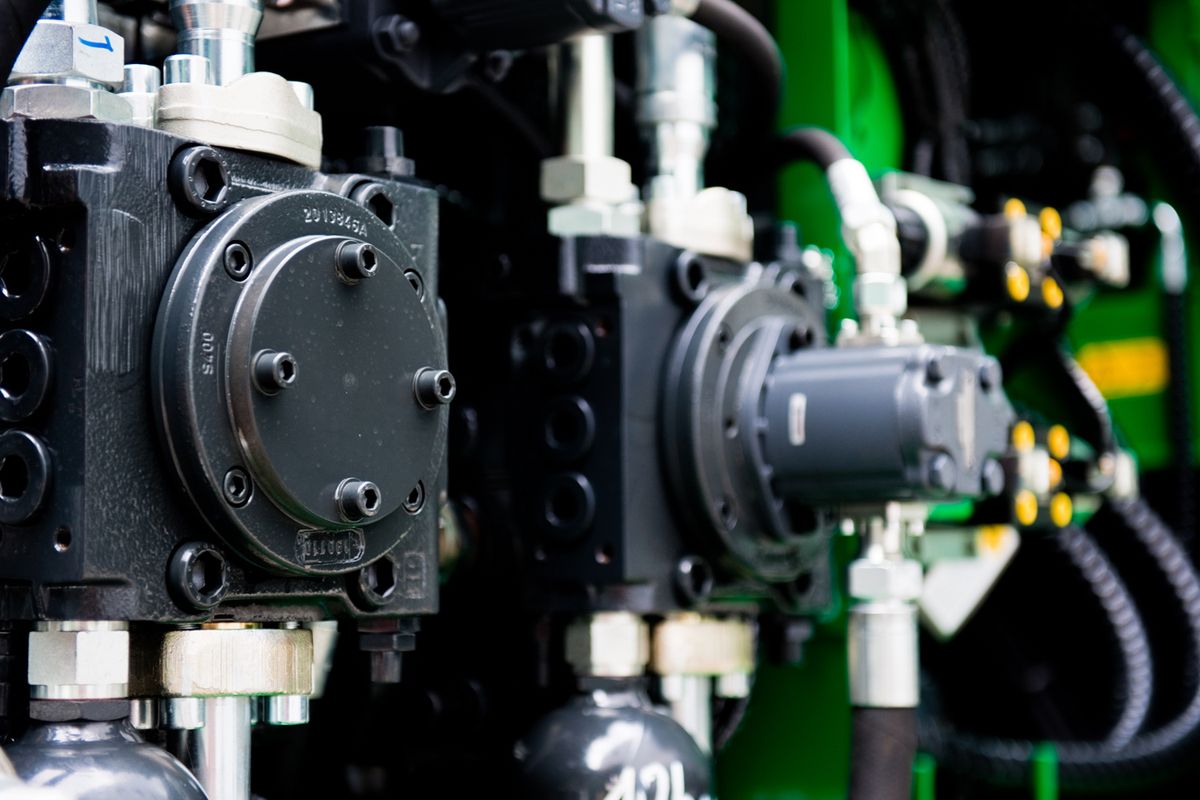

Komptech electric motors

The electric motor instead of a diesel engine offers a significant advantage in energy costs with its high efficiency. With comparable efficiency, 70% of energy costs can be saved compared to diesel.

Terminator counter comb

The counter comb is hydraulically controlled and allows you to continuously vary the size of the output material, increasing or decreasing the space between the counter comb and the rotor, this space can be set from the control panel or remote control even during the work phase.

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile

Terminator E-mobile