926M

The Cat 926M Small Wheel Loader sets the standard for productivity, fuel efficiency and operator comfort. The improved optimized Z-bar loader linkage delivers the quick loading performance of a traditional Z-bar with the parallelism and load handling capability of a tool carrier. A high torque, low speed C7.1 ACERT engine works in concert with an intelligent hystat power train to deliver fuel efficiency as standard. Meets Tier 4 Final/Stage V emission standards with an environmentally friendly, Clean Emission Module designed to manage itself so you can concentrate on your work. Experience the new industry benchmark.

Technical information

Features

Motore CAT C7.1 ACERT® Stage IV

Il motore Cat C7.1 ACERT®, Stage IV utilizzato in queste macchine utilizza la rigenerazione passiva a bassa temperatura che non ha nessuna necessità di combustibile aggiuntivo e NON NECESSITA’ DI NESSUN INTERVENTO DA PARTE DELL’OPERATORE, garantendo facilità d’uso sicurezza in qualunque applicazione.

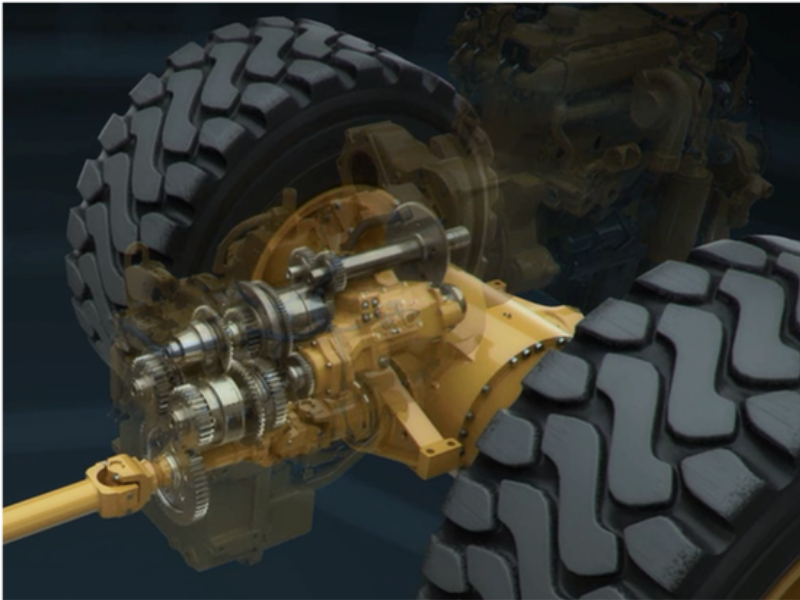

Continuously variable transmission

The Cat® continuously variable transmission is based on a hydraulic pump and a variator assembly that allows for a smooth and continuous variation of the transmission ratio between engine speed and machine speed. This makes it possible to reduce consumption by up to 25%, increase traction and power, even at low revs, and recover energy during deceleration to increase efficiency.

Parallel "Z" arm

The new parallel "Z" arm is able to maintain the parallelism of the loads during lifting and also to obtain high breakout forces, increase the discharge opening and the bucket closing angle. This system allows you to carry out all the jobs that previously other types of arm performed separately.

Electrohydraulic controls

The electro-hydraulic, ergonomic controls with very low drive effort and cushioned with the seat ensure high comfort throughout the entire work shift. The integrated button for changing direction and the sliding “slide” for proportional control of the third hydraulic function make work easier.

Instrument panel

The instrument panel with LCD display allows access to all the machine parameters and works in combination with the new control panel to adjust many operating parameters in real time. By means of an exclusive "help" key it is possible to query the machine on the functions that each command can regulate.

Cooling systems

Reversible variable speed hydraulic cooling fans with temperature sensors and large mesh radiators reduce fuel consumption, noise levels and blockages of the radiant mass, allowing the use of the machines in any application.

Area download

926M 930M 938M ITA ALHQ7475-00.pdf